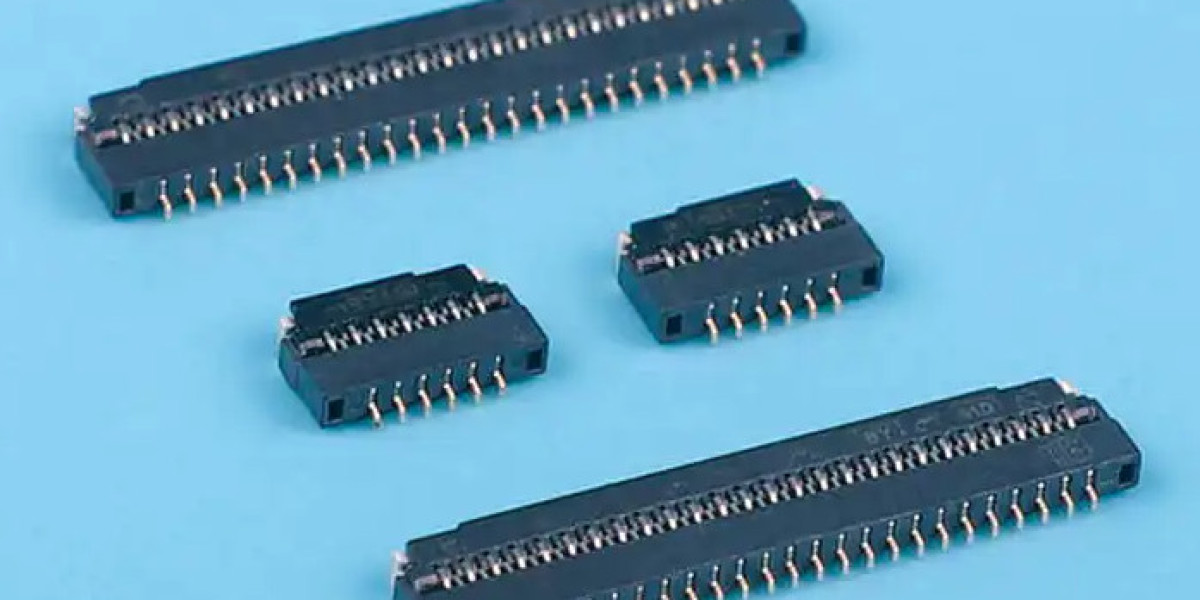

Understanding High-Frequency Signal Challenges

In modern electronic devices, high-frequency and high-speed signal transmission has become a fundamental requirement due to increasing data rates and compact product designs. At these frequencies, signal attenuation and crosstalk are no longer minor issues but critical factors that directly affect performance, reliability, and electromagnetic compatibility. When flexible circuits are connected to rigid PCBs, the interface must maintain impedance continuity and minimize unwanted coupling between adjacent signal paths. This is where the FPC Flat Connector plays a crucial role, especially in applications such as smartphones, cameras, automotive displays, and industrial control modules.

Controlled Impedance and Structural Design

One of the most effective ways to reduce signal attenuation is through controlled impedance design. High-quality connectors are engineered with precise contact geometry and spacing that closely match the impedance of the connected FPC traces. By minimizing impedance discontinuities at the connection point, signal reflections are reduced, allowing high-speed signals to pass through with less loss. Additionally, optimized housing materials with stable dielectric properties help maintain consistent electrical characteristics across a wide frequency range, which is essential for preserving signal integrity.

Crosstalk Reduction Through Pin Layout Optimization

Crosstalk is mainly caused by electromagnetic coupling between adjacent signal lines, a problem that intensifies as data rates increase and spacing decreases. Advanced connector designs mitigate this issue by carefully arranging signal and ground contacts. Ground shielding or interleaved ground pins between high-speed signal lines can significantly reduce capacitive and inductive coupling. This structural approach creates a more stable return path for signals and effectively isolates neighboring channels, resulting in cleaner signal transmission even under high-frequency conditions.

Material Selection and Contact Performance

Material choice also has a direct impact on both attenuation and crosstalk. High-conductivity copper alloys are commonly used for contacts to minimize resistive losses, while surface plating, such as gold, enhances contact reliability and reduces micro-level signal degradation. Insulating materials with low dielectric constants help reduce energy loss as signals propagate through the connector interface. Together, these material considerations allow the FPC Flat Connector to support higher bandwidths without compromising electrical performance.

Manufacturing Precision and Assembly Stability

Even the best design can fail if manufacturing tolerances are inconsistent. Precision stamping, molding, and assembly ensure that each contact maintains uniform pressure and alignment with the FPC pads. Stable mechanical engagement reduces micro-movements that could otherwise introduce impedance fluctuations and noise. In high-speed systems, this mechanical stability translates directly into electrical stability, helping maintain low attenuation and minimal crosstalk throughout the product’s operational life.

Supporting Future High-Speed Applications

As data rates continue to rise and device sizes shrink, connector performance becomes increasingly important. By combining controlled impedance structures, optimized pin layouts, advanced materials, and precise manufacturing, modern FPC Flat Connector solutions provide a reliable interface for high-frequency signal transmission. These design strategies not only address current challenges but also offer scalability for next-generation electronic products that demand faster, cleaner, and more stable signal connections.

1、CKT:4Pin to 50Pin

2、Current rating:0.5A AC/DC

3、Voltage rating(max):50V,AC/DC

4、Working Temperature:-25℃~+85℃,

(Including temperature rise in applying electrical current)

5、Contact resistance: Initial value ≤30mΩ

After environmental testing ≤50mΩ

6、Insulation resistance:≥500MΩ

7、Withstand voltage:500VAC(rms)

8、Applicable PCB board thickness:1.6mm to 2.0mm